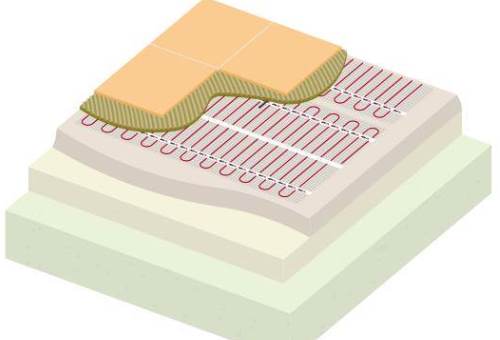

With their popularity increasing by the year, heated floors are rapidly becoming the norm for tilers when starting on a job.

Movement stress can build up in a heated floor during the heating and cooling cycles. Therefore it is important that the coefficient of thermal expansion of the rigid tiled finish does not vary too much from the heated sub-floor. This is because small changes in expansion and contraction exert greater stresses on rigid tile finishes. In addition, in order to reduce the risks of tiles cracking or de-bonding, adequate preparation and, where applicable commissioning of the floor heating system is crucial – as is the correct selection of adhesive and grout. Here we list the essential preparation for each type of system:

Hot water pipe system

If tiling onto a Hot Water Pipe system ensure the screed has fully dried. In the case of reinforced cement;sand based screeds this ranges from 6 days with BAL Quickset Cement to a minimum of three weeks for a screed containing OPC, before commissioning of the underfloor heating commences.

For anhydrite or alpha hemihydrate calcium sulphate screeds, surface preparation is also important. The drying time are dependent upon the thickness of screed and could be extended further , dependent upon site conditions. Further guidance may be sought from the TAS department or from the screed manufacturer.

Following this period of curing, the screed may be commissioned by heated slowly at a maximum rate of 5°C per day up to the maximum operating temperature as recommended by the heating manufacturer. The temperature of the screed should be maintained at this level for a minimum of three days, before allowing it to cool to room temperature.

Ensure that the heating system has been turned off, or on in cold temperatures, to ensure the screed is at 15°C before tiling commences.

Cable systems

When using cable systems check with the manufacturer to ensure the system is compatible with the intended substrate and application areas i.e. kitchen, bathroom etc.

The cables should be bedded into a layer of self-smoothing compound such as BAL Level Max. When using BAL Rapid Mat uncoupling system, the heating cables should be below the membrane and encased within the levelling compound.

Heating mats

Again check with the manufacturer that the chosen system is compatible with the substrate and to the environment it is being used in.

Before tiling, the surface of the mat should be primed using a contact adhesive, prior to the installation of tiles using the correct adhesive – which we will come onto.

Movement joints

Movement joints and control joints should be incorporated at all perimeters of the screed, including upstands or anything which penetrates the screed, such as columns or pillars. Movement joints are usually formed whilst the screed is being laid. Movement control joints should penetrate the full depth of the screed to the insulation layer.

Once tiling commences, movement joints should be incorporated to coincide those in the screed. For floors subject to thermal changes, such as under floor heating, floor areas should be divided up by movement joints into bays of size, not greater than 40m2 with and edge length of not greater than 8m.

If using BAL Rapid-Mat, the mat should be separated where intermediate movement joints penetrate through the thickness of the tile and bed down to the membrane placed on top of the reinforced screed base.

Suitable adhesives

When tiling onto concrete or cement: sand screeds or plywood overlaid floors (min thickness 15mm), a suitable tile adhesive is required

Suitable adhesives include: BAL Single Part Flexible, BAL Supercover Rapidset Flex, BAL Rapid Flex One, BAL Pourable One and BAL Max Flex Fibre.

For single layers of timber, or where plywood overlay is less than 15mm, consider the use of BAL Rapid Mat uncoupling mat and a flexible adhesive, or BAL Single Part Fastflex– a specialist rubber-crumb adhesive with elastomeric properties.

Suitable Grout

As with your adhesive choice, your chosen grout should also be flexible to allow for thermal movement. Recommended BAL grouts include: BAL Superflex Wide Joint Grout, BAL Micromax2 (with BAL Admix GT1 diluted 1:2 by volume with water when tiling onto single layers of timber of where plywood overlay is less then 15mm).

Due to the large number of heating system on the market, we would also recommend to contact BAL Technical Advisory Service (TAS) for advice before any work is carried out!

At BAL our Technical Advisory Service is fully equipped to provide support to contractors, architects and tilers – including NBS M40/M10/M20 specification assistance, on-site consultancy and expert technical advice.

Contact BAL Technical Advisory Service on 0845 600 1 222 or our Innovation and Technology Centre for training enquiries on 01782 591120.