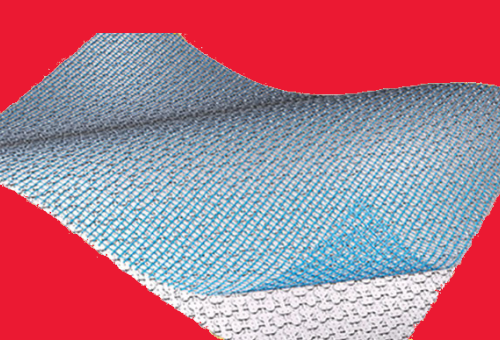

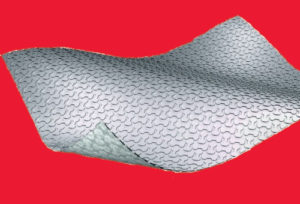

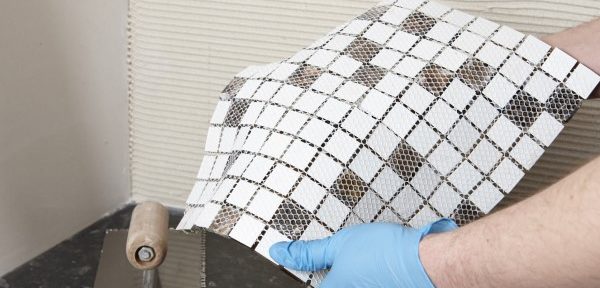

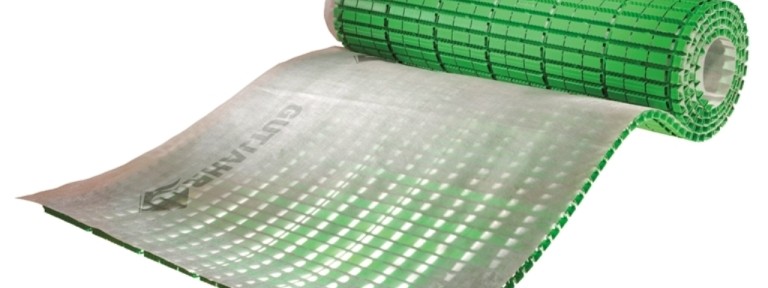

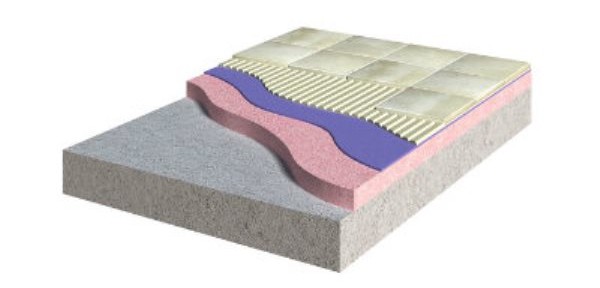

Introducing BAL Level Plus – a unique 1-part or 2-part rapid-setting smoothing and levelling compound, allowing you to use it however you need it for super smooth floors prior to tiling.

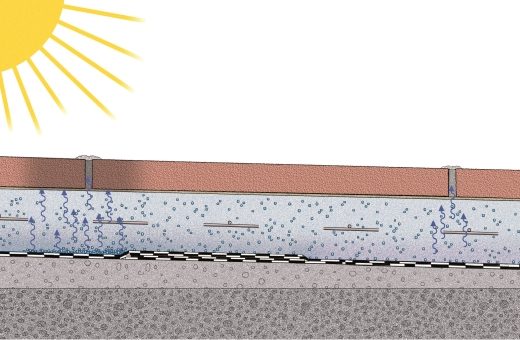

BAL Level Plus can be used as a 1-part mix with water for standard installations or as a 2-part mix with BAL Level Plus Liquid latex for a moisture tolerant levelling compound for more difficult substrates.

Use with water for good all-round performance on a number of common subbases including concrete, sand:cement screeds, anhydrite screeds, cementitious flowing screeds, unglazed tiles or stone, and old tile adhesive residues.

As a one-part mix, you can build BAL Level Plus up from 2mm to 12mm in bed depth – build-up to 30mm with the addition of aggregate.

For a superior enhanced performance, use BAL Level Plus as a 2-part mix with BAL Level Plus Liquid latex.

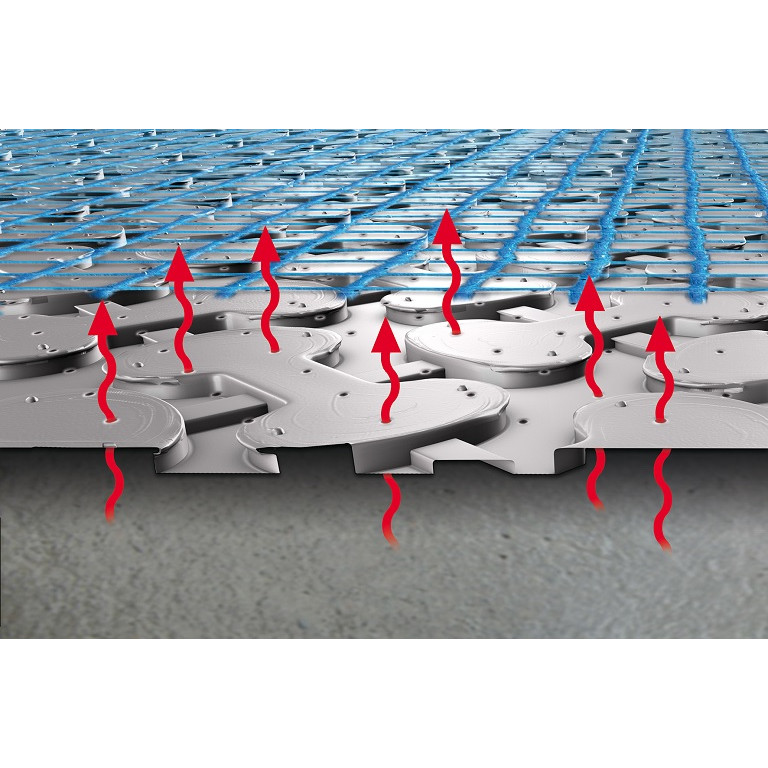

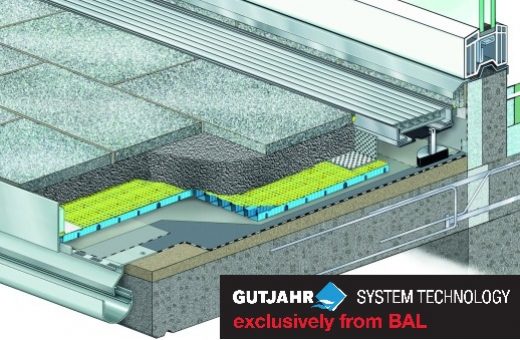

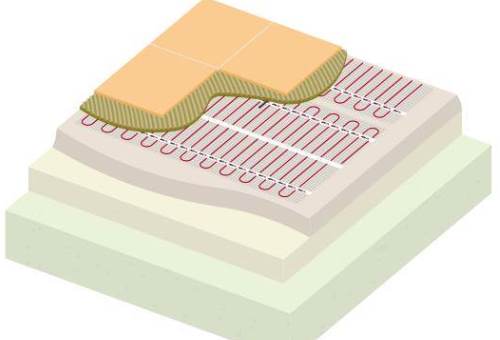

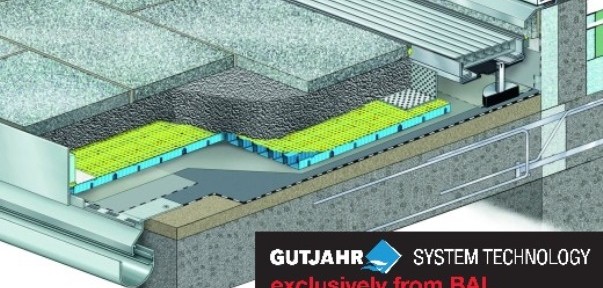

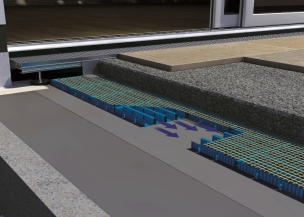

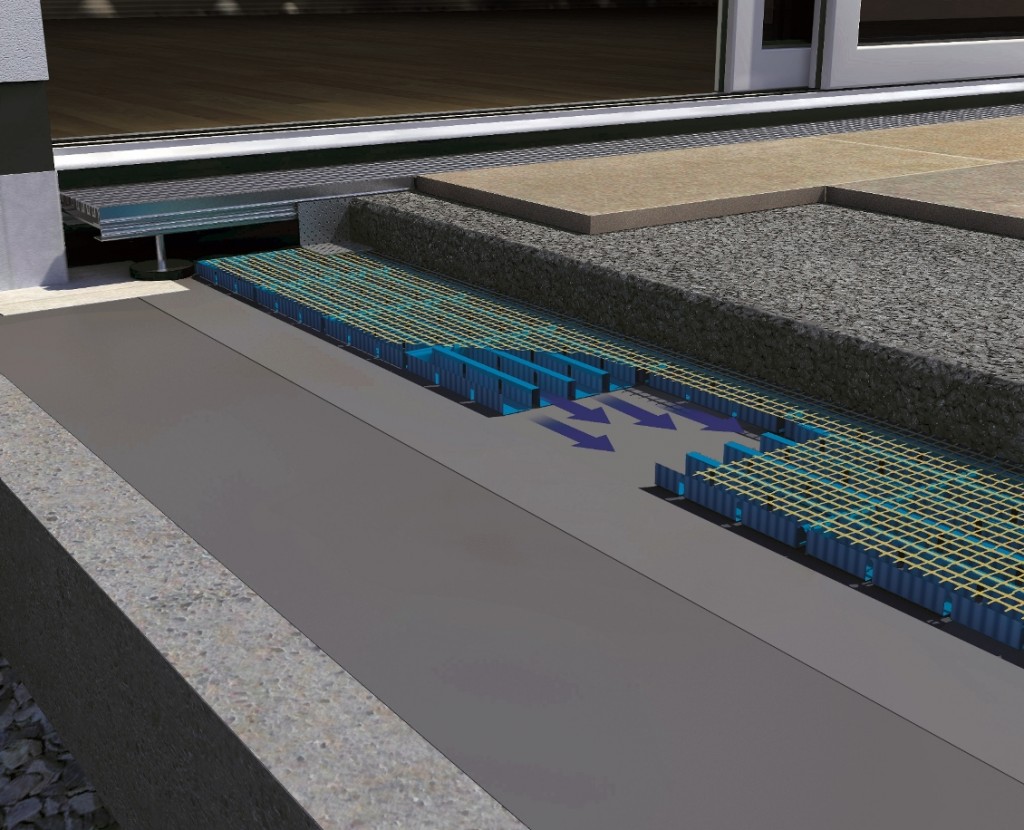

Use with BAL Level Plus Liquid over problematic substrates such as flooring grade bitumen, flooring grade asphalt, under-floor heating and heated screeds, direct onto glazed tiles, existing vinyl tiles (excluding LVT), and under DPMs – as part of an ARDEX Group moisture control system.

When used as a 2-part mix, BAL Level Plus can be used from 2mm to 10mm bed depth – or if you need to go deeper, it can be built up to 30mm with aggregate.

Whether you mix with water or latex, BAL Level Plus gives you a long pot life of 25 minutes and you can be tiling in as little as 2 hours for fast-track project completion.

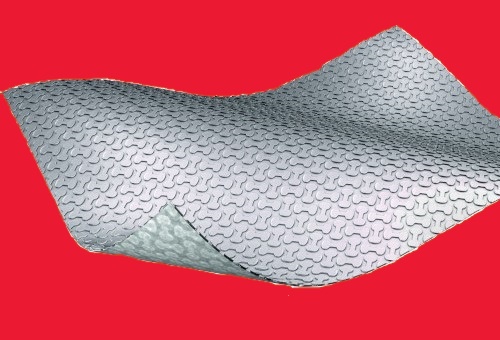

With great flow and self-healing properties, BAL Level Plus provides superior levelling. Suitable for spike-rolling, it provides a super flat surface perfect for tiling.

Alex Underwood, Head of Marketing at BAL, said the new product was yet another fantastic innovation by BAL to provide a perfect levelling solution for tilers.

“BAL Level Plus is a perfect solution for tilers and contractors,” he said.

“It gives the option of a really good 1-part leveller for most subfloors encountered on-site, but then for problematic floors, that they may find unexpectedly on-site – such as bitumen or old Marley vinyl tiles – they can mix Level Plus with the latex liquid for enhanced performance.

“It allows fixers or contractors to use it however they need to, making sure they can choose the most economical or performance driven solution they need, with just one product”

Double Points with GivBax Rewards

Did you know – if you download the GivBax Rewards app you can then use it to scan any

receipt or invoice with a BAL product purchased, to instantly get points on every BAL product – then redeem your points on merchandise, or CASH – directly from an ATM!

To celebrate the launch of BAL Level Plus – we’re giving DOUBLE POINTS on Level Plus Powder and Liquid until 7th October!

That means you’ll get 6 points (60p) from every bag, and 4 pts (40p) from every bottle!

Don’t miss out, start earning today! Download the App now through the App Store or Google Play.

Find out more about BAL Level Plus and GivBax Rewards at https://www.bal-adhesives.com/givbax/

ore than 20 years’ experience in the flooring sector, working alongside architects, specifiers, contractors and sub-contractors for companies including Altro, Polydeck Resins, and RSL. Key installations Alan has supported include flooring for Chelsea Football Club, Wimbledon, and BAA.

ore than 20 years’ experience in the flooring sector, working alongside architects, specifiers, contractors and sub-contractors for companies including Altro, Polydeck Resins, and RSL. Key installations Alan has supported include flooring for Chelsea Football Club, Wimbledon, and BAA.

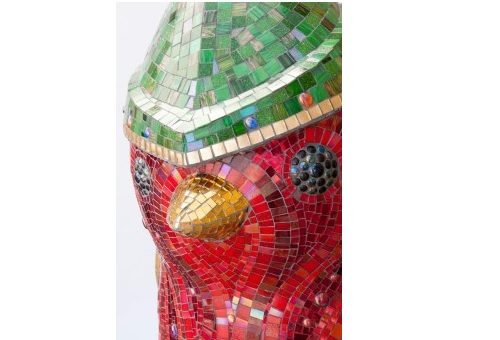

Dave, who joined BAL in 1992 after completing an apprenticeship in wall and floor tiling, was presented with the Outstanding Contribution to Industry award at The Tile Association Awards 2015.

Dave, who joined BAL in 1992 after completing an apprenticeship in wall and floor tiling, was presented with the Outstanding Contribution to Industry award at The Tile Association Awards 2015.