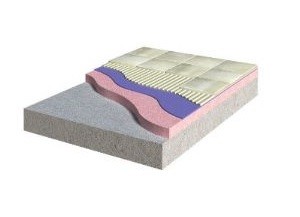

Calcium Sulfate or anhydrite screeds have grown in popularity over the last decade as they offer substantial benefits over traditional sand:cement screeds.

Easy to lay, low cost, fast-drying, pumpable, self-levelling and offering minimal shrinkage, anhydrite screeds are perfect for domestic or commercial projects. They are also suitable for underfloor heating so long as the pipes and associated heating elements are covered with at least 25mm of screed.

However, despite the numerous benefits associated with anhydrite screeds, fixers and installers need to aware of potential problems.

These types of screeds contain anhydrous (dry) Calcium Sulfate and aggregates instead of a cement-based binder. The binder comes as either an alpha hemi-hydrate (a stronger and harder crystalline form) or anhydrous Calcium Sulfate. When water is added the binders will form calcium Sulfate dihydrate – more commonly known as Gypsum. This reaction stops when the vast majority of the Calcium Sulfate binder is used up and is generally complete after a period of 3-7 days, leaving the remaining water to evaporate through the surface of the screed.

Before laying onto Calcium Sulfate screeds it is vital to ensure that the moisture content is at the correct level for the required floor finish. Typical values for moisture sensitive floor finishes are less than 0.5% Water by Weight or less than 75% relative humidity (RH) for impermeable floors and less than 1% w/w for more permeable floors. When fast-track tiling is required consider the use of a Damp Proof Membrane such as BAL DPM. BAL DPM can be used on anhydrite screeds up to 87% RH.

As a general rule thumb the drying time for a Calcium Sulfate screed, so the moisture content reaches 0.5% w/w, is approximately 1mm per day up to 40mm in ideal drying conditions – i.e. air temperature of 20C with a relative humidity not greater than 65%. Drying times will significantly increase for thicker screeds or those in poor drying conditions.

Accelerated drying of Calcium Sulfate screeds may be used once the screed is at least 7 days old. It is at this point that we would recommend commissioning any underfloor heating. The system should be increased by approximately 5°C per day until the maximum required working temperature is reached or as per the underfloor heating manufacturer’s recommendations. This should be maintained for a minimum of one week, before being gradually reduced to around 15-20°C. Do not exceed a temperature of 55°C. Use of dehumidifiers will also help.

Before laying tiles or other finishes onto Calcium Sulfate screed one of the most important tasks is the removal of laitance.

Laitance is a weak layer of fine particles deposited on the surface of the screed as the anhydrite cures. This layer is too weak to tile onto and can also inhibit drying of the screed. Many of the failures we see are as a result of contamination of the adhesive by laitance – highlighting the importance of carrying out this step.

Laitance should be removed by light abrasion using a suitable sanding machine i.e. a rotary floor scarifier and a 60’s grit sandpaper. Remove excess dust completely with a vacuum cleaner. Abrading the surface is best carried out 4-6 days after the application of the screed and can assist in the drying out process. Scarifying the surface is even recommended with low laitance Calcium Sulfate/anhydrite screeds as this further aids adhesion.

All traffic should be kept off the screed until it has hardened sufficiently in accordance with the screed manufacturer’s instructions and should always be protected from contamination and damage from other trades. It is best to protect the screed fully until the flooring is applied using boarding.

If not protected as the project progresses it may result in the wearing or grinding down of the screed’s surface. If this does occur then further surface treatment may be required. Moisture should also be avoided as any reintroduction of water can result in damage to the screed integrity and may affect any installed heating pipes.

Before tiling we would recommend applying a primer to the prepared screed surface before application of the tile adhesive. Priming created an effective barrier and assists in making the surface more stable.

When selecting your tile adhesive, consideration should be given to factors such as the tile type, and the type and method of cleaning the floor whilst in service – i.e. how wet the finished floor may become and what are the risks associated with limited water penetration. Slow or rapid-setting tile adhesives can be used, depending on the tile type and environment.

When the adhesive is cured, the joints between the tiles should be filled with a suitable grout – please note that a minimum of 3mm for floor tiling is recommended.

For ceramic tiling movement joints will be required in these installations. Any movement joint, or joints likely to be subject to movement, in the Calcium Sulfate screed should coincide with the movement joints in the tile bed. Movement joints should be incorporated as outlined in British Standard BS 5385-3, 2014 Clauses 6.8 and 7.1.6. For heated screeds also refer to The TTA technical document Tiling to Calcium Sulfate based screeds

Last, but not least, before tiling onto Calcium Sulfate screeds we would always recommend getting professional technical advice from manufacturers to ensure your installations look great and last the test of time.

By David Wilson, UK Technical Services Manager

(First published in Contract Flooring Journal)