What is a Resin Agglomerated Stone?

Resin agglomerated tiles have become an increasingly popular choice of floor finishes over the last 20 years, as they offer a cost effective alternative to natural stone. These tiles are manufactured in an array of colours and are ‘engineered’ to have some improved mechanical and physical properties such as scratch resistance and flexural strength. Resin agglomerated tiles are sometimes called reconstituted or re-composed stone and in the US are known as Engineered Stone.

A resin agglomerate stone tile is a composite material, based upon the use of recycled natural stone aggregates or stone pieces which are then bound together at the manufacturing stage using a synthetic resin. The resin bound stone is then formed by vibration and compression under a vacuum to form large blocks. These blocks are then allowed to cure before being sawn into slabs, calibrated to the correct size and thickness, polished, then accurately cut into the required tile sizes.

The agglomerated stone to resin binder ratio has a direct affect upon the physical, mechanical and performance properties of the tiles. For example, use of quartz or granite agglomerates produce in general a harder wearing tile with increased resistance to acidic chemicals when compared with those based on marble agglomerates. Two main types of polymer resin binder are used in the tile manufacture and these are either epoxide or polyester. Typically the ratio of resin binder to agglomerates varies from 5% to 7% (with 95% to 93% Agglomerate). The higher the percentage of resin present; then the greater the abrasion resistance is reduced. This is especially evident with increases in the Coefficient of Thermal Expansion of the tile.

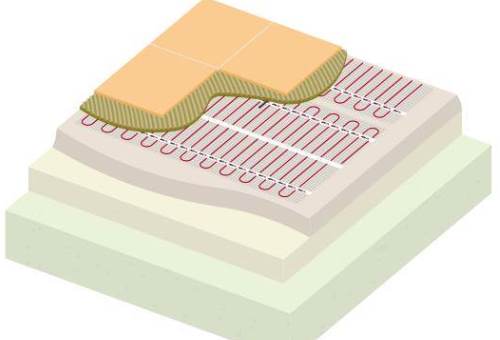

Thermal Movement

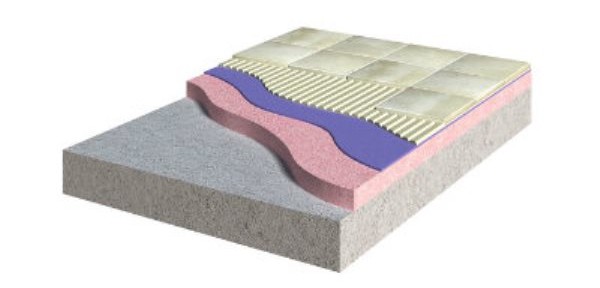

The use of underfloor heating or undertile heating is increasingly popular as a heating choice within the UK. It can often provide cost effective, comfortable and unobtrusive heating. When considering a rigid tile finish, either directly onto a heat source or in areas where thermal gradients exist i.e. areas subjected to direct sunlight. It is important to understand how the heat change affects the different materials employed within the tiling assembly.

Materials may undergo dimensional changes when subjected to heat fluctuation. This is known as the Coefficient of Thermal Expansion. When considering the tile, the tile adhesive and the substrate, the Coefficient of Thermal Expansion for a typical constructional sub-floor such as concrete or cement; sand screed is similar to a cementitious based tile adhesive. However a resin agglomerated stone tile has a higher Coefficient of Thermal Expansion in comparison. In simple terms the tile has a high modulus of rupture, or measure of strength before rupture, and is being ‘restrained’ by the tile adhesive. However due to heating and cooling cycles, a relatively small amount of heat expansion and contraction can exert a high level of stress on the restraining layer i.e. the tile adhesive. The larger the tile dimensions, the greater the magnitude of the dimensional changes on resin agglomerated stone caused by the thermal expansion or temperature increases.

Moisture Movement

It is important to note that resin agglomerated stone tiles do have varying degrees of moisture sensitivity which means that these tiles can be susceptible to differential moisture expansion. This can often lead to a potential ‘curling’ of the tiles. The Tile Association (TTA) technical document on Tiling with Resin Agglomerated Tiles recommends that:

“Cementitious floor screeds to receive resin agglomerated tiles should be completely cured and tested to ensure that they have a moisture content of not more than 2% by weight or 75% relative humidity using the appropriate test equipment and also that an appropriate adhesive is chosen” (Clause 3.5 Moisture Sensitivity).

Simply put, the use of a cementitious based tile adhesive or screed will introduce moisture directly beneath the resin agglomerated stone tile which may be taken up slowly by the tile. Some loss of moisture will occur whilst the tile joints remain unfilled; however this process will be slower. The tiles are available in various size formats including large formats (i.e. with one edge length 600mm or greater) up to typically 1200mm x 1200mm. The larger the tile in size, the more likely that moisture will become trapped at the tile/adhesive interface. In the case of some resin agglomerated tiles, this will increase the risk of curling of the tiles away from the tile adhesive bed. Therefore the correct selection of tile adhesive is essential.

For this reason, resin agglomerated tiles are not recommended for use infrequently wet areas e.g. areas of total immersion such as swimming pools or pool area walls and floors.

Adhesive Selection

Resin agglomerated tiles are classed as neither ceramic nor strictly speaking a natural stone, being as previously discussed as a ‘manufactured’ or ‘engineered’ stone tile.

However, British standards code of practice BS 5385: Part 5: 2009 and floor tiling Design and installation of terrazzo, natural stone and agglomerated stone tile and slab flooring – Code of Practice offers the following recommendations in clause 11.2.1 of BS 5385::Part 3 2014: “To avoid moisture from the adhesive bed distorting resin-based agglomerated stone, reaction resin adhesives, or quick drying low alkalinity cement-based adhesives should be used”.

BAL manufacture suitable rapid drying, low alkalinity tile adhesives. Dependent upon the background substrate to which the tiles will be fixed, BAL POURABLE ONE mixed with BAL ADMIX AD1 may be used for floors or BAL RAPID FLEX ONE with BAL ADMIX AD1 for walls. Where the resin agglomerate stone is especially moisture sensitive use of a suitable reaction resin tile adhesive i.e. BAL EASYPOXY AG may be specified.

Adhesive Application

When installing a ceramic tile or natural stone tile using a tile adhesive, the accuracy of a sub-floor should be such that when placing a 2 metre straightedge on the floor that there is no gap greater than 3 mm. This is known in BS 5385 Part 3 2014 as SR1 (Surface Regularity).

If this is not the case, this may be rectified by the use of a suitable smoothing and levelling compound such as BAL LEVEL MAX, dependent upon the type of floor construction.

In the case of the installation of large format tiles, in particular resin agglomerated stone tiles, the surface regularity should be SR1 or better for both wall and floor substrates.

The tile adhesive should be applied using a suitable notched trowel to the wall or floor and in the case of large format tiles, additional back buttering of the tile with the tile adhesive may be required to ensure adequate adhesive coverage.

When fixing resin agglomerate tiles to both walls and floors solid bed fixing is essential to;

- Ensure, as far as is practicable, full contact is achieved between the tile adhesive and the wall or floor tiles,

- Eliminate voids beneath the tiles, which in floors are potential points of weakness under load and in wet areas, moisture may become trapped from the service conditions on site or during regular cleaning.

Environmental Consideration

As previously discussed, resin agglomerated tiles are not recommended for use in frequently wet areas e.g. areas of total immersion such as swimming pools or pool area walls and floors.

For domestic showers and wet rooms, generally it is important to seek further advice from the tile supplier or manufacturer with respect to their fitness for purposes in these applications. It is also important to establish what, if any, additional precautions may be necessary to take both during and following completion of the tiling installation. Fundamentally the wall and floor should be protected from moisture ingress/ leaks using a suitable waterproofing tanking system such as BAL TANK-IT.

Additional protection from potential water ingress may be afforded by the use of a suitable impervious reaction resin grout such as BAL EASYPOXY AG or BAL FLOOR EPOXY. However, as stated in BS 5385-Part 4: 2015: “The use of impervious grouts and adhesives is no substitute for a tanked installation” (clause 7.2.3 Installations not immersed but subject to occasional wetting, note 2).

It is also important to note that the fixing of resin agglomerate stone tiles is not recommended for external tiling using a tile adhesive. Where the tile is deemed to be suitable for use for external application by the supplier or manufacturer, for external facades they should always be installed using appropriate mechanical fixings.

The Importance of Movement Joints

The need for inclusion of movement control joints within any tiled installation is well documented in the BS 5385: Parts 1-5 suite of standards. Fundamentally movement from factors such as drying shrinkage movement, thermal and moisture movement (as discussed previously) will generate stresses within the tiling system which can lead to de-bonding or cracking of the grouting and/or tiles.

Where the resin agglomerate tile is deemed to be suitable for floors subjected to direct heat or heat from an environmental source, The Tile Association technical document Tiling with Resin Agglomerated Tiles recommends the frequency of movement joints needs to be increased. For example, BS 5385-3 advises that for floors subjected to significant thermal changes, tiles should be divided into bays of size not greater than 40m² with an edge length not greater than 8m. In order to allow for the anticipated increase in thermal expansion of the resin agglomerated tile installation, the bays of size of the movement not greater than 25m² with an edge length not greater than 6m.

Under normal dry internal conditions, the advice is that bay sized should be reduced to bay sizes not exceeding 36m² (100m² bays for ceramic tiles).

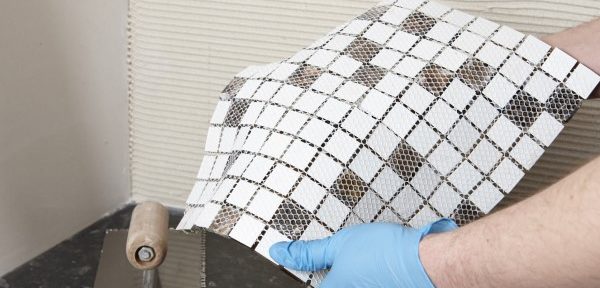

Mesh Reinforced Resin Backed Tiles

There has been an increase in recent years in the number of natural stone tiles i.e. marble or granite imported into the UK which has a mesh reinforced resin backing bonded to the lower interface of the stone.

Typically the resin polymers commonly used for this are epoxide, polyurethane or polyester of which polyester is the most commonly used. A fibre mesh is often embedded within the resin coating i.e. a fibreglass mesh.

The reasons for this vary from providing additional strength to the stone, particularly in the case of thin marble, limestone or granite, or sometimes it may be designed as a ‘temporary’ backing.

Unfortunately a polyester resin will have a much higher Coefficient of Thermal Expansion compared with the stone itself. Coupled with the surface of the resin which has a ‘waxy surface’ and may contain free styrene monomer, these will act as barriers to adhesion.

When fixing these mesh reinforced resin backed stone tiles, the bond strength achieved is totally dependent upon the quality and consistency of the resin/ mesh backing applied to the stone. This applies to both the dry and wet duty test conditions.

Factors which influence this are, for example;

- The tensile bond strength between the mesh reinforced resin backing and the stone, which can vary from strong to very weak.

- The chemical type of resin used e.g. polyester resin has a high coefficient of thermal expansion when compared with different types of stone and differing backgrounds/base.

- Variability in the quality and application of the mesh and resin between the same stone i.e. where mesh is not completely encapsulated in the resin or when the mesh is weakly bonded to the resin itself.

However the most fundamental factor when considering the feasibility of the use of a cementitious based tile adhesive conforming to the requirements of BS EN 12004: 2007 + A1: 2012 is that the tile adhesive is no longer bonding directly to the stone but to an intermediary (and potentially weaker) layer which has been introduced between the stone and the tile adhesive.

As an alternative to cementitious tile adhesives, reaction resin adhesives conforming to BS EN 12004: 2007 + A1 2012, could also be considered. However the use of a resin based i.e. an epoxide tile adhesive would prove to be very difficult, particularly where elevated temperatures may exist on site. In addition the amount of restraint offered to the mesh reinforced resin backed stone may counter-act against the anticipated levels of movement within any tiling installation, in particular where, for example any thermal and moisture movement is prevalent.

BS 8000: Part 11 Workmanship on building sites Part 11: Internal and external wall and floor tiling – Ceramic and agglomerated stone tiles, natural stone and terrazzo tiles and slabs, and mosaics – Code of Practice recommends that: “With large tiles and slabs any reinforcing mesh should be well adhered to the underside, and the mesh and adhesive should not obscure more than 25% of the underside of the tile or slab unless they are mechanically fixed”.

This advice mirrors that previous recognition is given for mesh backed mosaics which adhesives that the combination of mesh and glue holding the mesh in place should;

- Not cover more than 25% of the back of the tesserae

- Be no deterioration in the backing material and its glue whilst in service

- Be compatible with a cementitious tile adhesive in accordance with mosaic suppliers’ recommendations.

In conclusion, where a mesh reinforced resin backed stone is specified, unless the tile adhesive is able to bond directly to the stone to produce a contact area of 75% or more, it may be possible to consider removing the mesh reinforced resin backing altogether, but this must be undertaken following consultation with the stone supplier or manufacturer.

If this is not feasible to remove the backing without damaging the integrity of the stone, then consideration should be given to mechanically fixing. In the case of external wall cladding, BS 5385: Part 2 2015 advises that “Stone tiles which are resin mesh backed should not be used”.

When tiling with large format or natural stone floor tiles in colder weather – you may want to consider BAL XL Floor One.

When tiling with large format or natural stone floor tiles in colder weather – you may want to consider BAL XL Floor One.