How to choose the right levelling compound? BAL have a range of different solutions for you when floor levelling.

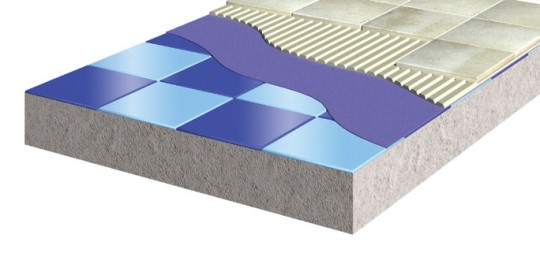

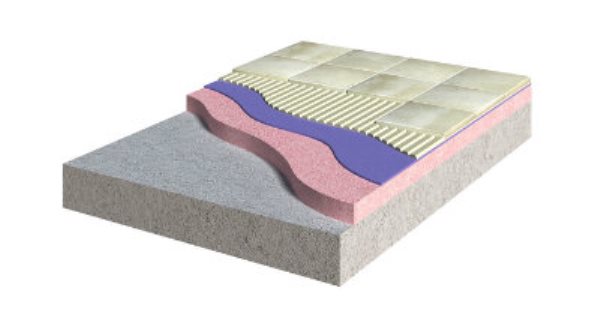

Smoothing and levelling compounds help level up small surface irregularities on new and existing bases and usually come in one-part or two-part forms. Easily mixed and simple to apply, they find their own level giving a smooth finish for laying tiles or other floor coverings.

Most smoothing and levelling compounds can only be applied up to 30-40mm and will need to be used in more than one application or with other materials required.

However, there are some exceptions on the market such as BAL Level Max which can be applied from 2 mm up to 80 mm in one application.

It’s always important to remember that most levelling compounds are not suitable as a finished, wearing surface, and that they should always be covered.

Typically; most smoothing and levelling compounds are suitable with most screeds, including sand:cement, anhydrite and flooring grade asphalt. However, when levelling timber floors, or screeds containing underfloor heating then only fibre-reinforced products are suitable i.e. BAL Level Max

When levelling over difficult substrates such as bitumen, tarmac, steel, and damp concrete, then specialist solutions should be used such as BAL Level Plus with BAL Level Plus Liquid.

Before laying a smoothing and levelling compound it is essential to ensure that correct preparation of the sub floor is carried out. Firstly ensure that the surface is clean, firm, dry and free from grease, dust and any other contamination which may be considered barriers to adhesion.

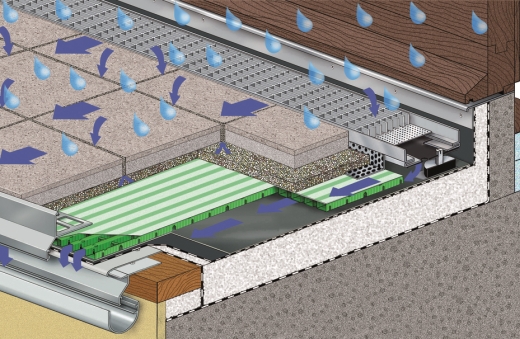

Any new concrete or screed must be left to fully cure according to the manufacturers’ instructions before applying any levelling compound. Ensure that any direct-to-earth sub-floors incorporate an effective damp proof membrane – such as ARDEX DPM, or DPM 1C.

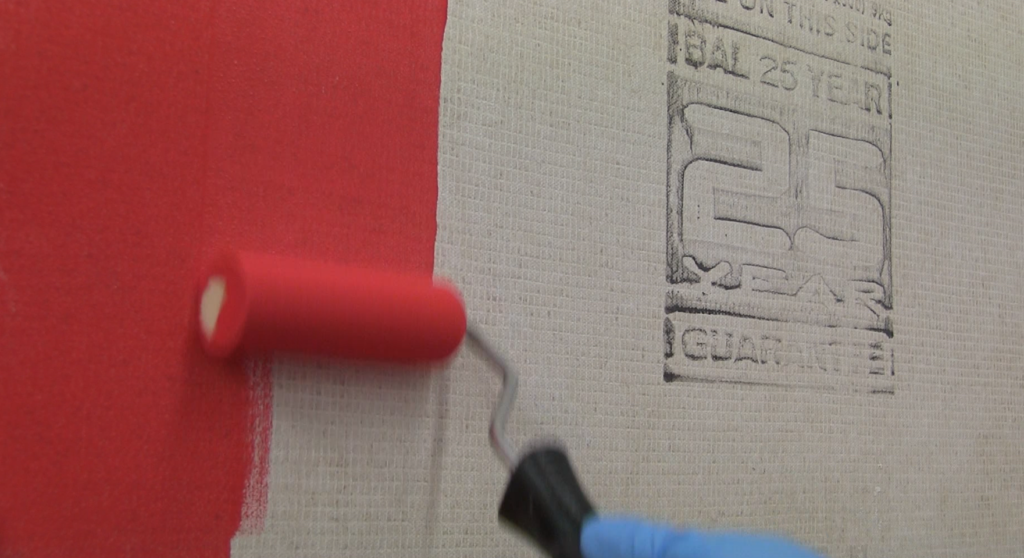

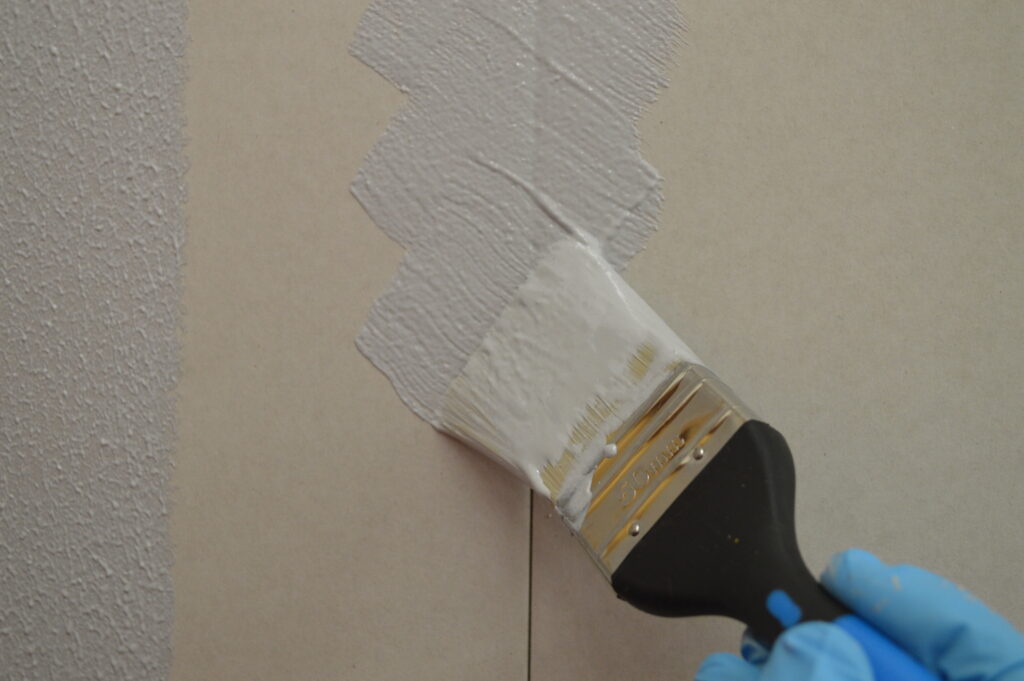

The majority of subfloors will also need priming. Floors such as concrete, cement:sand screeds, anhydrite screeds, cement:sand screeds with underfloor heated screeds and suitably constructed suspended timber floors.

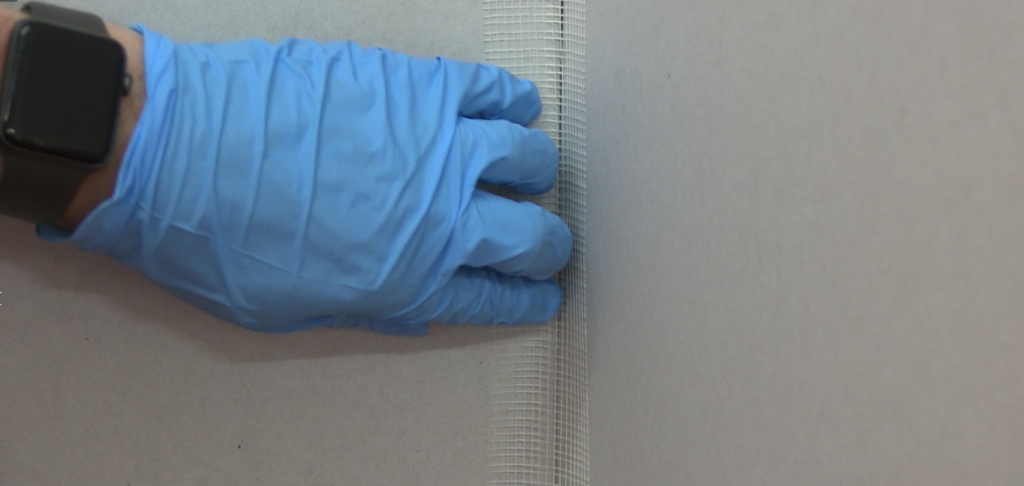

Priming ensures that the levelling compound fully adheres to the substrate, as well as extending the open times of levellers on porous floors. If levelling over timber boards where the joints are open, we would suggest using thin heavy duty tape to bridge the gaps.

When mixing your smoothing or levelling compound always ensure you follow the manufacturer’s instructions. We would always recommend mixing with an electric drill mixer at a slow speed i.e. under 300rpm. Always mix until a lump-free mortar is achieved and allow the mixed leveller to stand for two minutes before re-mixing for 30 seconds.

Once the required consistency is achieved, pour the mix over the prepared substrate and spread to the required depth using a suitable steel finishing trowel or long handled blade. Work the mixture well into the corners, edges and around projections. When you’ve finished spreading the mixture on the floor, pour some more mixture onto the floor and spread that out and blend it in with the previous area.

Before allowing to cure, ensure that the surface is sufficiently smooth to receive floor coverings without any further treatment. If you are laying tiles or slabs, floors should be corrected to SR1 (Surface Regularity) – this is plus or minus 3mm or less over a two meter straight edge.

We would not recommend the use of spiked rollers on a fibre-reinforced product (e.g. BAL Level Max) as this can pull fibres through to the surface, however a spiked roller is useful on non-fibre products – such as BAL Level Plus or BAL Level Out – to dissipate any air bubbles trapped in the compound.

If any trowel marks do remain, rub down before the compound has hardened.

Always allow the new floor to set before laying your finished floor surface. Setting times can vary depending on your chosen product normally between 3 to 24 hours and is dependent upon your floor finish.

For example, BAL Level Max can be tiled after 4 hours at any depth – even at 80mm. BAL Level Plus can be tiled between 2-3 hours.

For an even faster install, you can choose a rapid-setting leveller such as BAL Level Fast, this super-fast setting compound can be tiled in roughly 45 minutes!

In wet areas allow a minimum of 24 hours before waterproofing the levelled screed with a tanking system such as BAL Tank-it or BAL Waterproof 1C.

Finally, we would always advise checking with the manufacturer or their technical advisors for before application to ensure project success.

Covering the whole of the UK, ARDEX Group Training and Technical Support Managers offer practical knowledge and on-site consultancy and training to tiling and flooring contractors.

If you’ve experienced a problem on your installation whatever brand you’ve used, you can trust our TSMs to offer dependable solutions and remedies. What’s more, we’ll even send samples away for independent analysis at our laboratories to find the cause of the problem.

For more information on how to level a floor prior to tiling, contact our team today on 03330 030160.